Maximizing Value and Minimizing Risk Through Effective Supplier Management

What if you heard from a friend only once a year? Maybe each year you receive a birthday card to acknowledge your special day, or they call you when they need something. Do you feel a strong connection/relationship, or is it a case of out of sight, out of mind?

Is this how your organization treats suppliers? Once a year (if that) you contact them to acknowledge the renewal of a contract, or ask for lower prices/help with an issue. There is no real effort to nurture the relationship, understand performance, assess risk or explore joint opportunities. Is the assumption on performance that no news is good news and when you need help the supplier will simply jump to your command?

Is this how your organization treats suppliers? Once a year (if that) you contact them to acknowledge the renewal of a contract, or ask for lower prices/help with an issue. There is no real effort to nurture the relationship, understand performance, assess risk or explore joint opportunities. Is the assumption on performance that no news is good news and when you need help the supplier will simply jump to your command?

Unfortunately, this is how many organizations have historically approached Supplier Management. However, many organizations are now taking a much closer look at how they can conduct effective and efficient Supplier Management. Just as Strategic Sourcing was the trend 10 years ago, a significant shift is happening - companies are beginning to realize that continuing to ignore how they manage suppliers is a big mistake. Up to 30% of the value that is generated through a more strategic approach to sourcing is being lost due to poor Supplier Management.

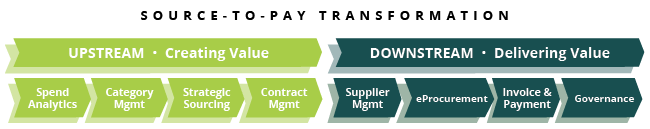

While the previous four blogs in our 8-Element series have related to finding and getting value, Supplier Management is focused on keeping and managing the value. Effective Supplier Management ensures that suppliers that are critical to operations are identified, classified, assessed and appropriate plans are developed to manage risk, performance and relationship issues.

So, what mistakes are commonly made by organizations when it comes to Supplier Management?

- Often it is viewed as a topic that they will "get to next year"...and it never happens.

- The value and impact effective Supplier Management can have on an organization is not understood. Executive stakeholders have a tendency to react to more visual/headline grabbing sourcing savings that are more immediately realized. Many people are blind to the risk and impact suppliers can have on the operation until it is too late. Only then is the real value truly understood.

- The organization is not structured to conduct effective Supplier Management - it is often viewed as a part-time role that resources will get to after they complete the 100 other tasks under their responsibility.

- Many organizations have thousands of suppliers, so they simply don't know where to start. Even those organizations that conduct some form of Supplier Management, it is often simply a case of taking the top suppliers by spend. Little thought goes into the impact on the business, future growth strategies or the categories that need stronger relationships to be nurtured.

- There is no methodology/process in place to actually drive the management of suppliers. Often organizations want suppliers to be managed, but don't provide the tools, technology or training to do it.

- Where supplier performance and risk are actually being addressed, it is too high level and reactive.

- Managing suppliers is often treated as a separate activity - the links to Category Management, Strategic Sourcing and Contracts are not understood or enabled. Key supplier performance, risk, relationship and pricing aspects should be identified earlier in the the value creation phase and where applicable contracted. This then forms the platform for Supplier Management and in turn a feedback loop on making better category and sourcing decisions in the future.

Do any of the above points resonate with how your organization is approaching Supplier Management? If yes, the good news is the trend is now moving to where organizations are beginning to see there is a better way to approach managing suppliers and are investing time and effort to make this change happen.

Nitor helps our clients become more effective at Supplier Management through a number of workstreams:

1. Develop Processes, Tools and Technology - Just like for aspects such as Category Management or Strategic Sourcing, in order to improve and drive consistency in how an organization manages suppliers, there needs to be a methodology/process, tools, training and have everything enabled through user-friendly technology. Provide trained resources the right tools and technology, then they can climb a new mountain. Unfortunately, one of the three key pillars to change - People, Process and Technology - is often forgotten by many organizations when developing Supplier Management.

Also, the connectivity between the various Source-to-Pay Elements is often overlooked and a silo approach is taken. The approach, processes and technology around Spend, Sourcing, Contracts, Supplier Management and eProcurement should all be integrated to aid efficiencies and visibility.

2. Segment The Supply Base - How do you identify which suppliers you should manage and how frequently? You likely have thousands of suppliers and cannot and should not manage all of them. The first key aspect in effective Supplier Management is therefore to segment your suppliers to ensure you are putting the resources, time, and effort into managing the key relationships. To segment, take a multidimensional approach - spend, risk, impact and business strategy. Don't make the common mistake and just look at spend - we have found every organization has suppliers that have relatively low spend, but the impact on the business (risk or revenue) is significant. Without this multidimensional approach, the consequence of not managing this type of supplier is unfortunately only understood after the event happens.

Segment your supply base into quadrants - we suggest Critical, Strategic, Preferred, and Transactional. This segmentation provides laser focus on where the most rigorous Supplier Management programs should occur - Critical and Strategic.

3. Review & Manage Supplier Performance - Do you truly know how your suppliers are performing? Or do they only get noticed when you have to deal with an issue impacting your business? Before you can understand how your suppliers are performing, you need to measure their performance against agreed requirements/KPI's resulting from the Category Management, Strategic Sourcing and Contract outputs. A supplier scorecard is developed to measure and monitor supplier performance and identify deficiencies in performance. Joint performance improvement plans are then developed, implemented and frequently reviewed to actively address issues. For suppliers that don't put the energy into addressing performance issues, this provides a formal feedback loop into Category Management and future supplier selection decisions.

A common issue is Procurement resources are concerned that managing supplier performance means a significant increase in their workload. This can be reduced by contractually placing the burden on the supplier to track and generate the reports.

4. Understand and Manage Risk - Do you remember the earthquake and tsunami that impacted Japan in 2011? The impact on various supply chains was immediate - automotive, technology, and many other industries were impacted by the interruption in the ability of suppliers to deliver products. This and other similar/localized events have caused some organizations to more deeply assess risks and associated business impacts. But, how can this become a more proactive rather than reactive environment to managing supplier risk?

The key is to conduct a risk assessment for the identified Critical and Strategic categories, ultimately developing a risk/impact score for suppliers. This is done through an internal review and conducting a supplier questionnaire.

Organizations with resulting joint risk mitigation plans are able to more quickly recover from issues than those with no plans - especially for the high risk/high impact areas. While you can never eliminate risk, you can certainly assess, mitigate and have a plan to manage it.

5. Develop Relationships with Suppliers - When was the last time your company's senior leadership met with your most critical and strategic suppliers to proactively develop the relationship? For that matter, when was the last time you took the time to go to the supplier's facility to get a first hand look at their processes and gather feedback from the people in the field who are providing your organization with key products/services? In addition to managing performance and risk, effective Supplier Management involves managing relationships. A common mistake is that organizations forget to focus on the "people" aspect of Supplier Management.

Establishing a relationship management framework helps understand the key relationship characteristics. Take the time to analyze the dynamics of the supplier relationship. Is the relationship a partnership or adversarial? Do you really understand how the supplier sees you as a customer? Do you have the stakeholders, both internally and at the supplier, identified and do you understand who is influencing the relationship? Is there an executive level relationship between companies for your most critical/strategic suppliers?

Once you understand the current state of the relationship, identify where you want it to go. Establish the strategic direction, collaboration level and communication plan with your Critical/Strategic suppliers and develop a path that will govern the overall relationship with the supplier. It is important to communicate this throughout the organization in order to establish a consistent approach and messaging.

6. Manage Organizational Change - A common mistake companies make that impacts the success of the above 5 workstreams, is they under estimate the importance of Change Management. Any time an organization is being requested to do things differently it is critical to drive awareness, collaboration and buy-in. It is also important to look at organizational structure, resources, skills and bandwidth to ensure that the new processes, tools and technology are actually utilized to enable effective Supplier Management.

While you can create a Supplier Management program without the previous four Elements - there will be a greater value from the program when all of the Elements are established and linked together:

- Element 1 - Spend Analysis will help with the supplier segmentation process.

- Element 2 - Category Management & Element 3 - Strategic Sourcing will produce the business requirements and KPI's for performance and risk management and establish the stakeholders for the relationship aspects.

- Element 4 - Contract Management legally captures all these key aspects and ensures the outputs and reports that aid Supplier Management will actually happen.

As you can see, the Elements are continuing to build and the work done in previous Elements will make the quality of the later Elements that much better. Be sure to check out the next blog on our 8-Element series about eProcurement. All our blogs are available at www.nitorpartners.com.

| Gary Stoddard | |

| Partner |

{{cta('c124d4a4-120d-4261-aa58-2c736d0de5a9')}}